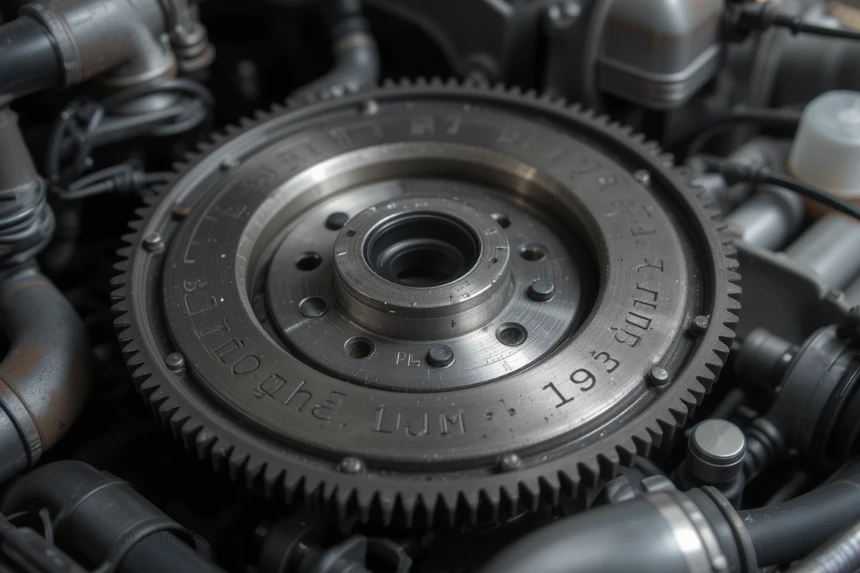

Introduction to 1994-1998 75-90 HP Flywheel Magnet

The period between 1994 and 1998 saw significant advancements in outboard motor technology, particularly in the development of reliable and efficient flywheel magnets for 75-90 horsepower engines. An essential part of the ignition system, the 1994–1998 75–90 flywheel magnet is in charge of producing the electricity required for engine functioning. Its quality and performance directly influence engine starting, smooth running, and overall longevity. In this article, we will explore the features, benefits, and installation tips related to this essential component.

Understanding the Role of the Flywheel Magnet

The flywheel magnet, also known as a permanent magnet, is embedded within the flywheel of outboard motors from that era. Its primary role is to produce a magnetic field that interacts with the stator to generate electrical current. The engine’s electronic parts, including the fuel and ignition systems, are powered by this current.

In engines from 1994 to 1998, especially those in the 75-90 horsepower range, the flywheel magnet must be durable, precisely manufactured, and capable of withstanding harsh marine environments such as saltwater corrosion and humidity. The quality of the magnet influences spark quality, engine response, and overall performance.

Key Features of 1994-1998 75-90 HP Flywheel Magnet

High-Quality Rare Earth Magnets: The magnet is often made from neodymium or similar alloys, providing a strong magnetic field essential for consistent electrical generation.

Corrosion Resistant Coating: Since marine engines are exposed to water, these magnets typically feature a protective coating to prevent rust and corrosion, thereby prolonging service life.

Precision Manufacturing: To ensure proper fit and optimal magnetic performance, these magnets are manufactured with tight tolerances.

Compatibility: The 1994-1998 75-90 hp flywheel magnet is compatible with various engine brands like Mercury, Yamaha, Evinrude, and Johnson from that era, making it a versatile replacement part.

Magnetic Strength and Stability: These magnets are designed to maintain their magnetic strength over long periods, even under high temperatures and mechanical vibrations common in marine engines.

Advantages of Using a Genuine 1994-1998 75-90 HP Flywheel Magnet

Reliable Engine Starts: A strong, stable magnet ensures a powerful spark, leading to easier starts even after periods of inactivity.

Improved Fuel Efficiency: Proper ignition timing enabled by a high-quality magnet ensures complete combustion, saving fuel and reducing emissions.

Enhanced Engine Performance: Consistent electrical generation means better overall engine responsiveness, smoother acceleration, and reliable operation.

Extended Engine Life: Using a durable magnet prevents early engine failure caused by weak spark or electrical inconsistencies.

Cost-Effectiveness: Investing in a genuine, high-quality flywheel magnet reduces the likelihood of frequent replacements and repairs, saving money over time.

Installation Tips for 1994-1998 75-90 HP Flywheel Magnet

Preparation: Disconnect the battery and clean the flywheel and magnet area to get rid of old corrosion, rust, and debris before installing.

Proper Alignment: Carefully orient the magnet inside the flywheel to ensure it fits snugly and is positioned to match the engine’s stator.

Torque Specifications: Use a torque wrench to tighten bolts to manufacturer-recommended specifications, preventing over-tightening that may damage the magnet.

Check for Magnet Strength: After installation, verify the magnet’s strength with a gauss meter to ensure proper magnetic output.

Test Run: Conduct a test run to confirm consistent engine performance and reliable ignition sparks.

Where to Find Genuine 1994-1998 75-90 HP Flywheel Magnets

Finding a genuine flywheel magnet from this specific era can be challenging, but reputable marine engine parts suppliers and authorized dealers often stock these components. It’s recommended to choose OEM parts or high-quality aftermarket equivalents that guarantee compatibility and durability.

Online marketplaces such as eBay, Amazon, and specialized marine parts websites are also good sources. Always check the product specifications, reviews, and return policies to ensure authenticity and quality.

Maintenance and Care Tips for Longevity

Regular Inspection: Periodically inspect the magnet for signs of corrosion, cracks, or damage.

Keep It Clean: Rinse the engine with fresh water after saltwater use to prevent corrosion on the magnet and surrounding parts.

Store Properly: When not in use for extended periods, store the engine in a dry, sheltered place.

Replace When Necessary: If the magnet shows signs of weakened magnetic strength or damage, replace it promptly to avoid performance issues.

Conclusion

The 1994-1998 75-90 hp flywheel magnet is a critical component that significantly influences engine performance, reliability, and longevity. Its quality and proper installation are essential for ensuring smooth operation and avoiding costly repairs. Whether you’re restoring an vintage engine or replacing worn components, investing in a genuine or high-quality magnet from this era guarantees optimal performance. Proper maintenance and timely replacement will keep your marine engine running efficiently and reliably for years to come.