Maintaining a diesel engine’s efficiency and longevity requires attention to many critical components, and one of the most vital is the engine ring tension. Proper diesel engine ring tension is essential for ensuring smooth operation, power output, fuel efficiency, and durability. In this comprehensive guide, we will delve into what diesel engine ring tension is, why it matters, how to measure it, and the best practices for maintaining optimal tension in your diesel engine.

What Is Diesel Engine Ring Tension?

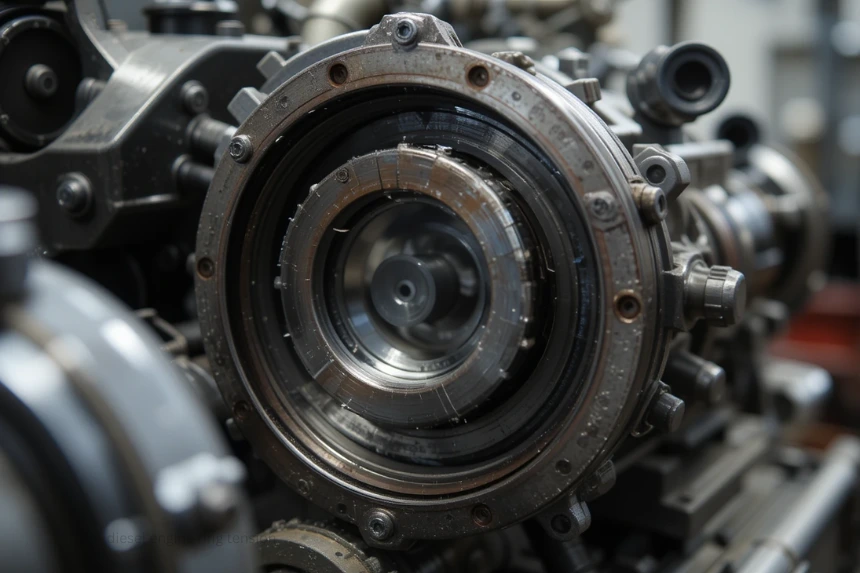

Diesel engine ring tension refers to the pressure exerted by the piston rings against the cylinder walls within a diesel engine. Piston rings are rings fitted around the piston, and their primary purpose is to seal the combustion chamber, control oil consumption, and transfer heat from the piston to the cylinder walls. The tension of these rings determines how effectively they perform these roles.

Proper ring tension ensures a tight seal, preventing compression loss, minimizing blow-by gases, and reducing oil leakage. Conversely, if the tension is too low, the rings may not seal properly, leading to decreased engine performance and increased emissions. If the tension is too high, it can cause excessive wear, cylinder wall scratching, and reduced engine lifespan.

Why Is Diesel Engine Ring Tension Important?

The significance of diesel engine ring tension cannot be overstated, as it impacts various aspects of engine operation:

1. Compression and Power Output

A precise seal between the piston and cylinder is maintained with the aid of optimal ring tension. This seal is crucial for achieving maximum compression, which directly influences the engine’s power output. A properly adjusted tension guarantees effective combustion, which improves engine performance.

2. Fuel Efficiency

When piston rings exert the correct tension, fuel consumption drops because the engine operates more efficiently. Poor ring tension leads to combustion gas leaks (blow-by), which diminishes fuel economy and increases emissions.

3. Engine Longevity

Proper ring tension reduces abnormal wear on piston rings and cylinder walls. Excessively tight rings can cause premature wear and cylinder wall damage, while too loose rings will cause poor sealing and increased wear due to increased movement and friction.

4. Oil Consumption and Emissions

Correct ring tension minimizes oil seepage into the combustion chamber, reducing oil consumption and lowering harmful emissions. Properly tensioned rings ensure the engine remains cleaner and runs more environmentally friendly.

How to Measure Diesel Engine Ring Tension?

It takes specific equipment and expertise to measure the ring tension of diesel engines.It often involves:

Visual Inspection: Checking the piston rings for signs of wear, cracks, or deformation during engine overhaul or maintenance.

Ring Gap Measurement: Measuring the ring gap clearance using a feeler gauge. This guarantees that the ring fits the cylinder correctly and with the appropriate tension.

Ring End Gap and Side Clearance: Ensuring the end gap and side clearance meet manufacturer specifications.

Ring Compression Test: Using a ring compressor to evaluate how the rings fit into the cylinder during assembly.

Using a Ring Tension Tester: This device applies a controlled force to the ring to measure its tension directly. These testers are typically used during manufacturing or engine repair.

Consulting the manufacturer’s specifications is essential when measuring or adjusting ring tension, as different engine models have unique tolerances.

Factors Affecting Diesel Engine Ring Tension

The ideal piston ring tension in a diesel engine depends on a number of factors:

1. Engine Wear and Age

Over time, piston rings and cylinder walls inevitably wear out, leading to a change in tension. Ideal tension levels are maintained with timely replacements and routine maintenance.

2. Temperature Variations

High operating temperatures can cause thermal expansion of engine components, affecting ring tension. Proper cooling systems and quality materials help manage these effects.

3. Quality of Piston Rings

High-quality piston rings are manufactured with precise tolerances to maintain consistent tension. Lower-quality rings may wear unevenly or fail to hold proper tension.

4. Assembly and Installation Processes

Incorrect installation, including improper ring gap alignment or inadequate lubrication, can adversely affect ring tension and engine performance.

5. Lubrication

Over time, inadequate lubrication changes the tension by increasing wear and friction.

Best Practices for Maintaining Optimal Diesel Engine Ring Tension

Proper maintenance practices are crucial for sustaining ideal diesel engine ring tension:

Regular Inspections: Periodically check piston rings for signs of wear, deformation, or damage.

Follow Manufacturer Specifications: Always adhere to the specifications provided by the engine manufacturer regarding ring gap, tension, and installation procedures.

Use Quality Replacement Parts: Invest in high-quality piston rings and components designed for your engine model.

Engine Overhaul and Rebuilding: During rebuilds, ensure precision in piston ring installation and tension measurement.

Maintain Coolant and Lubrication Systems: Proper cooling and lubrication prevent thermal expansion issues and reduce wear.

Monitor Engine Performance: Abnormal engine behavior, such as increased oil consumption, smoke, or loss of power, may indicate ring tension issues that need addressing.

Conclusion

In summary, the diesel engine ring tension plays a critical role in the overall performance, efficiency, and durability of diesel engines. Maintaining the correct tension ensures a proper seal, optimal compression, and minimized wear—all of which translate into an efficient and long-lasting engine.

Whether you’re performing routine maintenance or rebuilding an engine, understanding and managing ring tension should be a priority. Proper measurement, adherence to manufacturer guidelines, and using high-quality components will help keep your diesel engine running smoothly for miles to come.