When selecting a heat pump for your home, understanding the system’s airflow capacity is crucial for ensuring optimal performance and comfort. A common question among homeowners and HVAC professionals alike is: “How many CFM does 1.5 ton heat pump produce?” This article aims to answer this question in detail, exploring the relationship between tonnage and airflow, the factors influencing CFM production, and how to ensure your system operates efficiently.

Understanding CFM and Its Importance in HVAC Systems

Before diving into specifics, it’s essential to understand what CFM means. CFM stands for Cubic Feet per Minute, a measurement of airflow volume in a heating, ventilation, and air conditioning (HVAC) system. Adequate airflow ensures that the conditioned air distributes evenly throughout the space, maintaining consistent temperatures and humidity levels.

Too little CFM can lead to uneven heating or cooling, reduced system efficiency, and increased wear on components. On the other hand, too much airflow can lead to discomfort and noise problems, thus it is critical to match the right CFM to the capacity of your system.

How Tonnage Relates to Airflow: The Basics

In HVAC, “ton” refers to the system’s cooling capacity. One ton of cooling is equivalent to 12,000 British Thermal Units (BTUs) per hour. The widely recognized general rule of thumb in the industry is:

1 ton of cooling requires approximately 400 CFM of airflow.

This standard provides a baseline for designing or evaluating HVAC systems, including heat pumps. Based on this, a 1.5-ton heat pump would generally produce:

1.5 tons×400 CFM/ton=600 CFM

1.5 tons×400 CFM/ton=600 CFM

So, a 1.5-ton heat pump should ideally produce around 600 CFM of airflow.

Factors Affecting CFM Production in a 1.5 Ton Heat Pump

While the 400 CFM per ton rule is a helpful guideline, actual airflow can vary depending on several factors:

Manufacturer Specifications: Different brands and models may have slightly different airflow ratings based on design efficiencies or features.

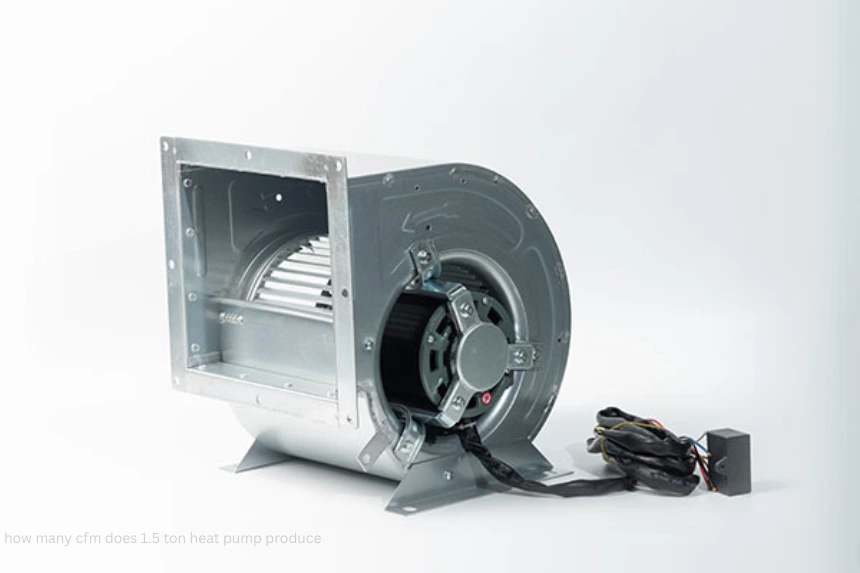

Blower Motor and Fan Speed: The power and speed settings of the blower motor influence the volume of air moved.

Duct System Design: Properly designed ductwork ensures the system can deliver the rated CFM without excessive noise or pressure drops.

Filters and Obstructions: Clogged filters or blocked vents can reduce airflow, lowering effective CFM.

System Age and Condition: Older or poorly maintained units may not achieve their rated airflow capacity.

Because of these factors, always consult the manufacturer’s specifications or an HVAC professional for precise measurements.

Why Accurate CFM Is Critical for Your Heat Pump’s Performance

Ensuring your 1.5-ton heat pump produces the correct CFM is more than just a technical detail; it directly affects comfort, efficiency, and equipment longevity. Proper airflow:

Enhances Dehumidification: Correct CFM helps remove excess moisture from the air, improving indoor comfort.

Prevents System Short Cycling: Adequate airflow maintains stable indoor temperatures and prevents the system from turning on and off too frequently.

Extends Equipment Lifespan: Consistent airflow reduces strain on the compressor and blower motor.

Optimizes Energy Use: Properly balanced airflow minimizes energy consumption and lowers utility bills.

How to Determine if Your Heat Pump Has the Correct CFM

If you’re unsure whether your 1.5-ton heat pump is delivering the right airflow, here’s what you can do:

Consult the Manual or Manufacturer Data: Check for the specified CFM for your model.

Measure Airflow with an Anemometer: Professionals can use an anemometer to measure air velocity at vents and calculate actual CFM.

Assess Vent Conditions: Ensure filters are clean, vents are unobstructed, and ductwork is appropriately sized and sealed.

Hire a Professional for System Evaluation: HVAC specialists can perform airflow tests and make adjustments, such as changing blower speeds or correcting duct issues.

Adjusting CFM for Optimal Performance

If your system is producing less than the recommended 600 CFM for a 1.5-ton unit, adjustments may be necessary:

Increase Blower Speed: Adjusting the blower motor speed can raise CFM.

Modify Ductwork: Installing appropriately sized ducts or sealing leaks improves airflow.

Replace or Clean Filters: Dirty filters restrict airflow and should be replaced regularly.

Upgrade Blower Components: Some systems allow for higher-capacity blowers to increase airflow.

Conversely, if CFM is too high, it might cause noise or discomfort, and steps should be taken to reduce airflow, such as lowering blower speed or installing dampers.

Conclusion

How many CFM does 1.5 ton heat pump produce? Based on industry standards of 400 CFM per ton, a 1.5-ton heat pump should typically generate approximately 600 CFM of airflow. However, actual airflow can vary depending on system design, maintenance, and ductwork.

Ensuring your heat pump delivers the correct CFM is essential for optimal comfort, efficiency, and equipment lifespan. Regular maintenance, professional assessments, and proper duct design are key to achieving and maintaining the right airflow levels.

If you’re experiencing uneven heating or cooling, inadequate airflow, or higher energy bills, consider consulting with an HVAC professional to evaluate and adjust your system. Properly balanced airflow ensures your 1.5-ton heat pump performs at its best, providing reliable comfort for years to come.