Understanding how tight are diesel engine valves is essential for maintaining optimal engine performance and longevity. In a diesel engine, valves are essential for managing the flow of fuel, air, and exhaust gases. If their clearance or tightness is not properly maintained, it can lead to performance issues, increased emissions, and even engine damage. This article explores the significance of valve tightness in diesel engines, how it is measured, and the impact of improper valve clearance on engine health.

The Role of Valves in Diesel Engines

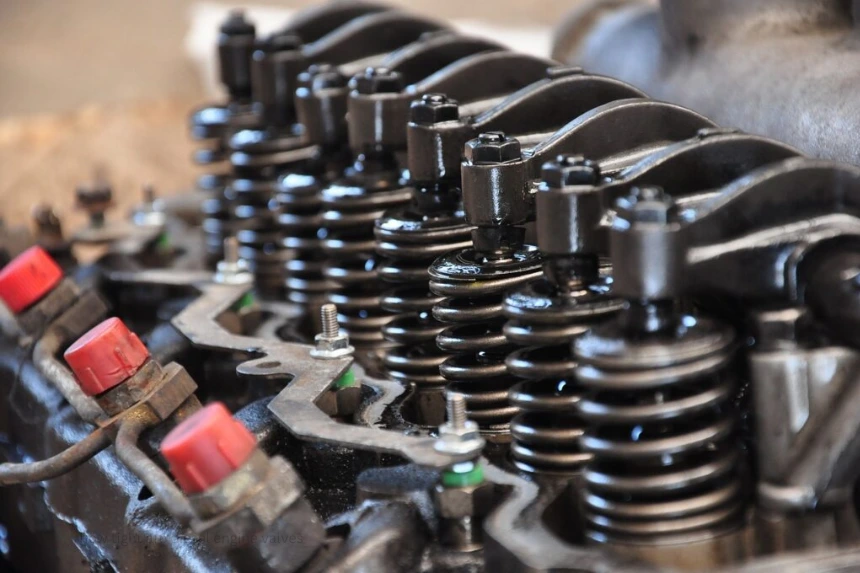

Diesel engines employ valves to regulate the intake of air and the discharge of exhaust gasses, just like other internal combustion engines.Intake and exhaust valves are the two primary varieties. They open and close in precise synchronization with piston movement, allowing the engine to breathe efficiently.

Maintaining the right clearance, sometimes known as valve lash, between the valve and the camshaft is critical to effective valve performance.This clearance ensures that valves seat properly and seal effectively during operation. If the valves are too tight or too loose, it can cause a cascade of issues affecting engine efficiency and durability.

How Tight Are Diesel Engine Valves?

The question of “how tight are diesel engine valves” relates to the valve clearance or lash—specifically, how much space exists between the valve tip and the camshaft lobe when the valve is closed. The tightness of these valves can vary depending on the engine design, manufacturer specifications, and operating conditions.

Typical Valve Clearance Range

The valve clearance for the majority of diesel engines, including heavy-duty and common rail variants, typically falls between 0.1 and 0.3 mm (0.004 and 0.012 inches). However, this range can be different depending on the engine’s make and model. Manufacturers provide specific clearance values, which are usually listed in the service manual.

Are Diesel Valves Usually Very Tight?

In many diesel engines, especially modern designs, valves are set to be relatively tight to ensure a proper seal and prevent combustion gases from escaping. A tighter valve clearance minimizes the risk of valve leakage during combustion, leading to better compression and fuel efficiency.

However, “tight” should not mean so close that it prevents the valve from closing completely or causes excessive wear. Precision adjustments are necessary to strike the right balance.

Why Valve Tightness Is Crucial

Proper valve tightness directly impacts engine performance, emissions, and durability. Here is why:

1. Ensures Proper Compression

A tight, well-seated valve that forms a tight seal keeps the engine’s compression ratio constant. Increased fuel consumption, rough idling, and power loss can result from loss of compression.

2. Prevents Valve Leakages

If valves are too loose, gases can escape during compression and combustion, leading to misfires, rough running, or even valve damage over time.

3. Reduces Valve Train Noise

Incorrectly adjusted valves, especially too loose, produce ticking or tapping noises, which are signs that the valves are not closing properly.

4. Enhances Fuel Efficiency and Emissions

Complete combustion is ensured by properly calibrated valve clearance, which lowers pollutants and increases fuel efficiency.

How to Check and Adjust Valve Tightness in Diesel Engines

Checking how tight are diesel engine valves involves measuring the valve clearance with specialized tools. The process generally includes:

- Removing engine parts such as valve covers.

- Using feeler gauges to measure the gap between the valve tip and camshaft lobe.

- Comparing measurements with manufacturer specifications.

- Adjusting the clearance by adding or removing shims or adjusting the rocker arms.

Regular maintenance schedules usually specify when to check and adjust valve clearance. For many diesel engines, this can be done during routine service intervals after a certain number of operating hours or miles.

Consequences of Incorrect Valve Tightness

Significant engine issues can result from improper valve adjustment, including:

Valve Burning or Damage: Excessively tight valves may not fully close, leading to hot spots, valve burning, or cracking.

Reduced Power: Loose valves cause incomplete combustion, resulting in power loss.

Increased Fuel Consumption: Leakage and poor sealing decrease engine efficiency.

Engine Knocking or Ticking: Noisy valve operation often indicates improper clearance.

Premature Wear: Both tight and loose valves accelerate wear of valve components, damaging the camshaft, rockers, and valve seats.

Maintaining Proper Valve Clearance in Diesel Engines

Given the importance of how tight are diesel engine valves, regular inspection and maintenance are vital. Here are some best practices:

- Follow the manufacturer’s recommended service intervals.

- Use precise measurement tools such as feeler gauges.

- Adjust clearance according to specifications to ensure optimal performance.

- Replace worn valve components promptly.

- Consider professional servicing for complex or heavy-duty engines.

Final Thoughts

A crucial component of engine maintenance is highlighted by the query, “How tight are diesel engine valves?” Long engine life, good power delivery, and effective combustion are all guaranteed by proper valve clearance. While modern diesel engines are often designed to operate with tight clearances to maximize performance, any adjustment or inspection should be performed carefully and according to manufacturer guidelines.

Regular maintenance, including checking valve clearance, can prevent costly repairs and keep your diesel engine running smoothly for years to come. If you’re unsure about the proper settings for your specific engine, consulting a professional mechanic or the vehicle’s service manual is always recommended.