Introduction

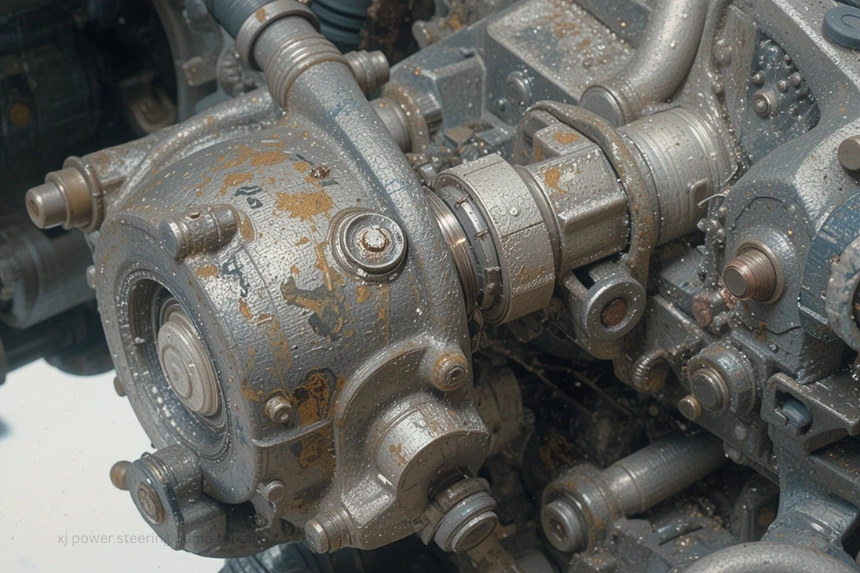

When it comes to maintaining and repairing your Jeep XJ, understanding the components involved is essential for ensuring smooth operation and safety. One critical part of the power steering system is the power steering pump, which relies heavily on precise threading for proper attachment and function. In this article, we will explore the intricacies of the XJ power steering pump threads, their significance, common issues, and how to address them effectively.

What Are XJ Power Steering Pump Threads?

The XJ power steering pump threads refer to the threaded portions of the pump that allow it to be securely mounted to the vehicle’s steering system components. These threads are designed to create a tight seal for fluid lines and ensure a secure connection with other parts such as the pulley, hoses, or mounting brackets.

In the Jeep XJ, which is a popular model among off-road enthusiasts and daily drivers alike, the power steering pump threads are typically standard sizes compatible with common fittings. However, over time, these threads can become stripped, damaged, or misaligned, leading to leaks or even pump failure.

The Importance of Correct Threads in Power Steering Pumps

Proper threading in the power steering pump is vital for multiple reasons:

Preventing Leaks: Improper or damaged threads can cause fluid leaks that diminish steering performance.

Ensuring Secure Connection: Correct threads keep the pump securely attached, preventing vibrations or detachment during operation.

Maintaining System Pressure: Tight and well-formed threads ensure the hydraulic pressure needed for smooth steering.

Ease of Maintenance: Tasks involving installation and repair are made easier by consistent thread size and quality.

XJ Power Steering Pump Standard Thread Sizes and Types

The typical XJ power steering pump threads include:

Inlet and Outlet Fittings: Usually standard AN or BSP threads, but often specific to the OEM specifications.

Mounting Bolts: These may vary but are generally metric sizes, commonly M6 or M8, depending on the model year and specific setup.

It’s important to always verify the thread specifications when replacing or repairing parts to avoid mismatched fittings, which can cause leaks or damage.

Typical Issues with XJ Power Steering Pump Threads

Despite their importance, XJ power steering pump threads are prone to several issues:

1. Thread Stripping

Repeated disassembly or overtightening can strip the threads, making it difficult to create a seal or secure attachment.

2. Corrosion and Rust

Exposure to moisture can cause corrosion on the threads, which weakens their integrity and impacts sealing.

3. Cross-threading During Installation

When fittings are installed incorrectly, the threads may become damaged and need to be repaired or replaced.

4. Leaks Due to Damaged Threads

Damaged or worn threads can cause leaks in the power steering system, leading to loss of hydraulic pressure and steering difficulty.

How to Identify and Diagnose Thread Issues

Detecting problems with XJ power steering pump threads involves:

Visual Inspection: Examine the threaded fittings for visible corrosion, debris, or rust.

Leak Checks: Notice any fluid leaks around fittings or between the pump and hoses.

Performance Symptoms: Hard steering, unusual noises, or inconsistent response may indicate thread-related issues.

Disassembly Inspection: Look for indications of damage or stripping on the threads when removing the pump or fittings.

Repair and Replacement of Power Steering Pump Threads

XJ power steering pump thread issues can be fixed in a number of ways:

1. Re-threading or Helicoil Repair

For minor damage, thread repair kits like helicoils can restore the original thread size and integrity.

2. Replacing Damaged Fittings

In cases of severe damage, replace the fittings or the entire pump if necessary.

3. Using Proper Torque and Techniques

To avoid further damage, make sure fittings are tightened in accordance with the manufacturer’s instructions.

4. Upgrading to High-Quality Fittings

Invest in durable, corrosion-resistant fittings to improve longevity and performance.

Preventative Measures for Maintaining XJ Power Steering Pump Threads

Prevention is always better than repair. To maintain the best possible condition for your XJ power steering pump threads:

Use Proper Tools: Always use the correct size and type of tools when installing fittings.

Apply Lubricants: Use appropriate thread lubricants or sealants to facilitate installation and sealing.

Avoid Cross-threading: Carefully align fittings during installation.

Regular Inspection: Periodically check for corrosion, leaks, or damage.

Protect Fittings from Elements: Store or cover the vehicle to prevent moisture accumulation.

Conclusion

The general condition and functionality of your car’s steering system are greatly influenced by the XJ power steering pump threads. Proper understanding, maintenance, and timely repairs of these threads can prevent costly damages and ensure your Jeep XJ delivers reliable performance. Whether you’re replacing fittings, repairing damaged threads, or simply inspecting for issues, paying attention to this small yet crucial component can make a significant difference in your vehicle’s operation.