Owning a Mazda Miata, especially the popular ND model, offers a thrilling driving experience combined with the joy of customizing and maintaining your car. One unique aspect of car maintenance that often goes unnoticed is the cabin air filter. In recent years, a fascinating trend has emerged: ND Miata cabin air filter 3D printed. With this creative method that blends technology and usefulness, auto enthusiasts may design premium cabin air filters that are customized for their ND Miatas. Let’s explore this trend, its benefits, the process involved, and how it can revolutionize your car maintenance routine.

The Importance of the Cabin Air Filter in Your ND Miata

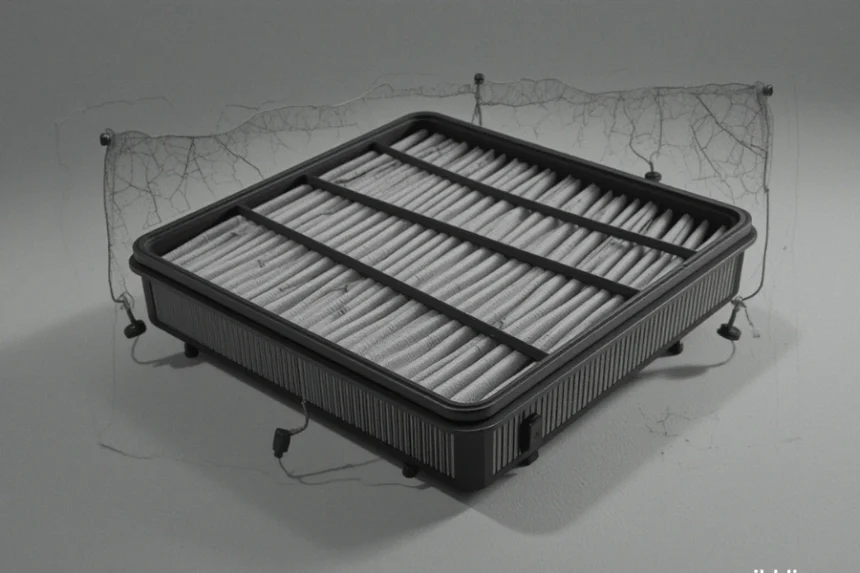

Before diving into the world of 3D printing, it’s crucial to understand why the cabin air filter matters. Located within the HVAC system, the cabin air filter ensures the air circulating inside your vehicle remains clean and free from pollutants, pollen, dust, spores, and other airborne contaminants. For drivers who frequently navigate through urban areas or rural environments full of allergens or pollutants, a high-quality cabin air filter is essential for comfort and health.

Traditional cabin air filters are typically purchased from auto parts stores, with options varying from basic to high-efficiency filters. However, these filters often have limitations in customization, cost, and availability. That’s where the nd miata cabin air filter 3d printed option opens new possibilities.

Why 3D Printing for ND Miata Cabin Air Filters?

3D printing has revolutionized various industries, from aerospace to medical devices, and car maintenance is no exception. For ND Miata owners, 3D printing offers several distinct advantages:

Customization

Every driver has unique needs. Whether you want a specific size, shape, or filter material, 3D printing allows for customization that factory-produced filters simply cannot match. You can design a filter that perfectly fits your ND Miata’s cabin air intake.

Cost-Effective Production

While purchasing premium filters can be expensive over time, 3D printing can reduce costs, especially for DIY enthusiasts. Once the initial design is created, multiple filters can be produced at a fraction of the cost of commercial products.

Rapid Prototyping and Iteration

If a certain design doesn’t fit perfectly or doesn’t filter as efficiently, modifications are quick and easy with 3D printing. This process enhances the overall performance and ensures the filter meets your specific requirements.

Access to Innovative Materials

Modern 3D printers can use various materials, such as flexible thermoplastics or porous filaments, suitable for creating effective filter substrates or housings that mimic or enhance the filtration properties of commercial filters.

The Process of 3D Printing a Cabin Air Filter for Your ND Miata

Creating a 3D printed cabin air filter involves several steps, from design to printing and installation. Here’s a detailed look at each phase:

1. Designing the Filter

The first step involves designing the filter using CAD (Computer-Aided Design) software. Accurate measurements of your ND Miata’s existing cabin air intake are essential to ensure a perfect fit. Several online communities and forums, such as Reddit or Mazda enthusiast groups, often share CAD files for custom parts, which can be modified or directly used.

2. Selecting the Right Material

Choosing the appropriate filament is vital. For filters, porous or fiber-reinforced materials are ideal. Some enthusiasts use flexible thermoplastics like TPU or special antibacterial filaments to improve airflow and filter longevity.

3. Printing the Filter

The printing process can start as soon as materials and design are complete. It’s important to monitor the 3D printer to ensure quality and consistency. Depending on the complexity, a single filter may take several hours to complete.

4. Adding Filtration Media

The printed body serves as the frame or housing. The filtration media—such as activated carbon or HEPA filter paper—must be integrated into the design. This step can be DIY or done by professionals who understand filtration requirements.

5. Testing and Installation

Before installing in your vehicle, the filter should be tested to verify fit and airflow. Once confirmed, it can be installed in the cabin air intake, replacing or upgrading existing filters.

Benefits of ND Miata Cabin Aair Filter 3d Print

Opting for a nd miata cabin air filter 3d printed offers numerous benefits:

Tailored Fit: Steer clear of problems caused by aftermarket filters that do not fit properly.

Enhanced Filtration: Design improvements can lead to better purifying capabilities.

Sustainability: Reusable or adaptable, they cut down on waste that comes with throwaway filters.

Technical Satisfaction: DIY customization adds a sense of achievement and deeper understanding of your vehicle.

Challenges and Considerations

While the idea of 3D printing your cabin air filter is exciting, it does come with certain challenges:

Material Safety: Not all 3D printing materials are suitable for parts exposed to air and pollution. It is essential to make sure the filament is non-toxic and safe.

Filtration Efficiency: The filter’s effectiveness hinges on the filtration media incorporated, not just the housing.

Expertise Required: CAD design and 3D printing require technical skills, though many online resources can help beginners.

The Future of 3D Printing in Car Maintenance

The trend of nd miata cabin air filter 3d printed is part of a larger movement towards personalized and sustainable automotive maintenance. As 3D printing technology advances, we can expect even more sophisticated, efficient, and eco-friendly solutions for car enthusiasts. From custom filters to engine components and interior accessories, the possibilities are virtually endless.

Final Thoughts

The idea of creating a nd miata cabin air filter 3d printed is an exciting fusion of technology and car culture. It allows owners to take control of their vehicle’s maintenance, ensuring cleaner air inside the cabin while enjoying the process of customization. If you’re a tech-savvy Mazda enthusiast, exploring 3D printing for your cabin air filter might just be the next step in elevating your driving experience.

By leveraging innovation, you can not only improve your ND Miata’s comfort but also gain a deeper appreciation for the intricate relationship between technology and automotive care. Embrace the future of DIY car upgrades—your engine (and lungs) will thank you!